Effortless, Secure, Flexible, Reliable

Our Grout Sleeve Socket Fixing Magnet System is the perfect solution for fixing rebar connection sockets without the need for punching holes in the platform. With a holding force of 160-240kgs, our strong rare earth magnets provide a secure hold for precast concrete production. The high performance rubber and magnetic fixing system eliminates the need for screws, saving time and labor costs in the production process.

● Strong and Efficient Hold

● Specially Designed for Precast Concrete

● Versatile and Easy to Use

● Reliable and Popular Choice

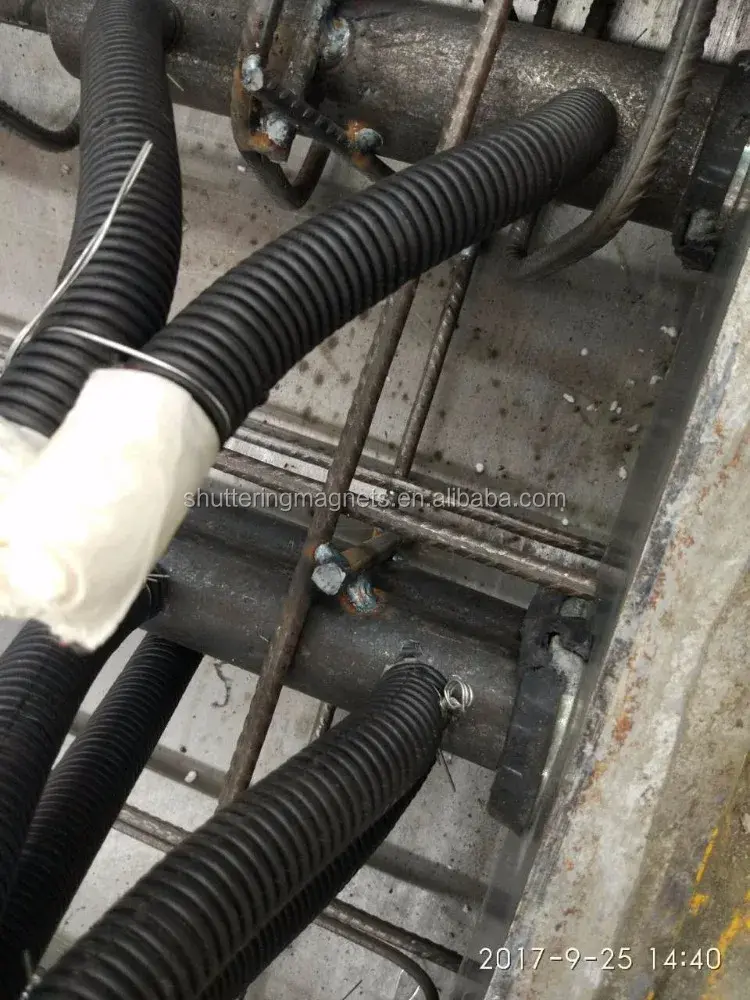

Product Display

Enhanced Productivity and Safety: Revolutionary Magnet System

Effortless and Secure Fixture

The Grout Sleeve Socket Fixing Magnet System is a diameter 70mm magnet system specifically designed to fix rebar connection sockets, with a holding force of 160-240kgs thanks to strong rare earth magnets. The high-performance rubber provides enough elastic force to hold the socket in place and the magnet power is sufficient to firmly fix the socket onto the side form during precast concrete production. With the ability to suit grout sleeve sizes from D20 to D50 and easy removal from the platform, this magnet system is a popular choice in the precast concrete industry.

◎ Strong

◎ Convenient

◎ Elastic

Application Scenario

Material Introduction

Our socket fixing magnet system offers the benefit of avoiding the need for punching holes in the platform when fixing the grout sleeve, saving time and effort during the precast concrete production process. With a strong holding force of 160-240kgs, our rare earth magnets ensure secure and tight fixation of the socket onto the side form, eliminating the need for manual fixing and freeing up manpower for other tasks. The high performance rubber and magnetic fixing method make our D70mm magnet system the ideal solution for grout sleeve fixation, suitable for sizes ranging from D20 to D50, and easily removable from the platform, making it a popular choice for precast concrete factories worldwide.

◎ Grout Sleeve Socket Fixing Magnet System Material Introduction

◎ 160-240kgs Precast Concrete Formwork System Material Introduction

◎ Hassle-free and efficient rebar connection Material Introduction

FAQ

Company Advantages

· The production of SAIXIN inserted magnet suppliers is in compliance with the industry defined norms and guidelines.

· Its quality is ensured for a better global competitiveness.

· NINGBO SAIXIN MAGNETIC TECHNOLOGY CO.,LTD makes efforts to comprehensively enhance the operational efficiency and quality.

Company Features

· NINGBO SAIXIN MAGNETIC TECHNOLOGY CO.,LTD is a professional manufacturer in China. We have been recognized as an excellent company for our inserted magnet suppliers.

· SAIXIN has a complete inserted magnet suppliers production laboratory, which can produce more elaborate products.

· With the business culture of "the pursuit of innovation, the inherit of quality", we aim to become of the strongest leader in the inserted magnet suppliers industry. We will learn from strong competitors, and introduce international advanced technology to help us achieve this goal.

Application of the Product

Saixin Magnetic's inserted magnet suppliers is widely applicable in the industry.

According to different needs of customers, Saixin Magnetic is capable of providing reasonable, comprehensive and optimal solutions for customers.