Providing Solutions of Magnetic Fixing to Precast Concrete Industry

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

SXB-1802

SAIXIN

10pcs per wooden box

30days

SAIXIN

steel with magnet

1350kgs*2

1-5years

Product Description

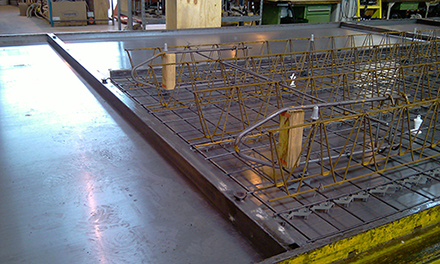

Shuttering base with different profiles can be specifically made for customer requirements, for example slab supports, wall corner joints and many more.

We develop SXB-1802 shuttering system exactly according to your needs and requirements. Please do not hesitate to contact us.

MAGNETIC SHUTTERING SERIES

SAIXIN shuttering systems have good outstanding qualities under tough practical testing. Our magnetic shuttering systems can be used flexibly, rapidly, safely and efficiently in every field.

Key Features:

1. high-performance magnets, strong force secure the shuttering against sliding.

2. easy positioning, fixing and removal of the shuttering, either in manual, crane or robotic handling.

3. provide a cost effective, efficient solutions for the production of high quality precast concrete elements.

4. special tailor-made shape, height & length, on the basis of your individual requirements.

We also can produce shuttering as per your design.

We provide customized services, special tailor-made shape, height & length are on the basis of your individual requirements.

Please do not hesitate to contact with us.

SHUTTERING TECHNOLOGICAL PROCESS

Steel plate steel section

flattening ↓ ↓ straightening

Cutting cutting

↓ ↘ ↙

Bending drilling

↘ ↓

welding

↓

straightening

↓

Polishing → milling

↓ ↙

inspection

↓ pass

painting

↓

Assembling with magnet system

Application

Instruction

There is an ON/OFF button on the top of the magnetic shuttering. At work state, press the button, the shuttering fix on the platform firmly, Pull up the button with lever, shuttering is at closed state and can be moved.

The suction force is based on the height and length of the shuttering. SAIXIN® magnetic shuttering is composed of permanent neodymium magnets and high-strength steel. In theory, if the MAX working temperature is below 80℃ and the magnet is not damaged or corroded, the suction will be lasted forever.

Maintenance And Safety Guidelines

(1) In order to avoid the magnetic shuttering damaging, do not crash and use hard tools to knock it.

(2) Magnet system of the shuttering touching surface should be kept clean and smooth, avoid the scrap iron or concrete grout going inside it, otherwise the button flexible degree will be affected and the magnet system will be slanted, caused the shuttering can not be fixed on the platform closely and the suction weakened.

(3) Shuttering touching surface should be kept clean and smooth always. After using, clean the shuttering. And it should be oiled when storage. Max working and storage temperature should be below 80℃,and no corrosive medium around. Always check if the working surface fix the platform closely and the button flexible degree to ensure the normal use.